PRESSURE BLOWERS CO.

PB Humidifiers, a Division of Pressure Blowers Co. is proud to

introduce the most advanced Commercial Humidifiers in today's

market:

Power Steam Humidifiers

General Description:

General Description:

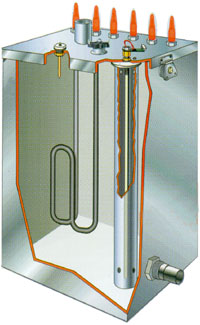

Our power humidifiers designed to provide dry sterile steam for

humidification.

They combine the latest microprocessor based electronic

design with carefully matched metallurgical and mechanical

technology perfected over

two decades. The design is based on permanent

rather than

replaceable containers.

The SKR humidifier is

easy to install and provides a simple and reliable operation with the

user friendly control package. Steam is produced in a permanent

stainless steel chamber which is easily removed and re-installed for

rapid servicing. No plastic cylinders to replace, making it more

economical to operate and environmentally friendly than the electrode

humidifier.

• No expensive plastic cylinders to buy

• Environmentally friendly - no plastic cylinders to throw away

• No more blocked drain solenoid valves

• Drain water tempered to below 14

This element type electric power steam humidifier has the following

features:• Capacities from 4.5–12lb/hr (2-5.5kg/hr) of steam.

• On/off operation, modulation optional.

• Permanent cleanable stainless steel evaporation chamber.

• Self-cleaning elements.

• Siphon drain requires no drain valve or external tap.

• Simple control wiring using pre-assembled cables with telephone jacks.

• Easy to install, operate and maintain

Simplicity of Operation and Service:

The humidifier consists of an automatically water fed stainless steel

container with an easily removable cover containing heating elements

and water level sensors.

Periodic servicing of the unit can be easily done in minutes. All mechanical, power and control connections are readily accessible for quick servicing.

The mechanical and electrical compartments are secured by wide hinged doors allowing comfortable inspection and access to all components.

Exceptional Reliability:

Reliability of our humidifier is one of the features that set it apart from competing humidifiers. Using the proprietary AFEC technology, this humidifier is much more forgiving to variable water conditions. Great care has been taken to select materials which have proven themselves for their exceptional performance in very harsh conditions. Such materials are elements made of super alloy, incoloy 825, teflon sleeved stainless steel level control probe, silicon tubing and baked enamel painted aluminum cabinet.Selection of electro-mechanical and electronic components has been based on many years of experience and exhaustive testing. All units pass through rigorous Q.C. inspection and full power check.

Features:

- Permanent, easily serviceable stainless steel container

- ON-OFF or MODULATING control functions

- Interactive LCD display and microprocessor controlled self-diagnostics

- AFEC technology provides greatest energy conservation and safest operation

- Functions exceptionally well in severe, normal or D.I. water conditions

- Self-cleaning heating elements

- Unit is built from the most advanced materials such as stainless steel and teflon components and silicone hoses

Aluminum housing and the best electronic and electro-mechanical parts

Anti-Foaming Energy Conservation System:

The AFEC technology developed by our engineering team offers a unique safety and energy conservation management of expensive boiling water and steam. The AFEC system is made of a mass measuring water sensor, anti-foam sensor, electronic high temperature sensor, interactive LCD display and microprocessor controller.The AFEC system is unique because:

The water sensor cannot be falsely triggered by foam formation on the top of the boiling water. This eliminates the problem of heating elements burning out in free air.

The additional foam-sensing probe, which is unique to our design, would automatically initiate a drain cycle upon foam formation. Unlike other humidifiers, the drain can be initiated only when necessary without having continuous skimming to drain expensive boiling water. This is an excellent energy conservation measure.

Suppliers of Canada Blower industrial process and OEM fans and pressure blowers, high temperature blowers, high pressure fans & ventilators. Delivery from stock of centrifugal and axial process fans, blowers, ventilators and humidifiers. ventilating.com fanblower.com highpressureblower.net industrialblowerfan.com industrialfanblower.net industrialfanblower.com pressureblower.net northernindustrialsupplycompany.com industrialpressureblower.com tenderall.com chicagoblowercanada.com cbblower.com buffaloblower.com buffalofan.com nis-co.com canadianblower.com olegsystems.com canadablower.com abbblower.com acmefan.net industrialblower.net fansandblowers.net americanblower.net barryfan.com cincinnatifan.net canadafans.com barryfan.net