Centrifugal Roof and Wall Exhaust Fans

Upblast power roof ventilator designed for the exhaust of grease-laden air from restaurant range hoods, and general ventilation applications where vertical discharge of exhaust air is required. Applications include all types of commercial and institutional kitchens, such as restaurant and cafeteria, fast food , hotel and motel, bakery, delicatessen, school, hospital and military.

Sizes 12 to 44

150 to 30,000 CFM

to 3" Static Pressure

Downblast roof exhausters are quiet, dependable power roof ventilators recommended for a wide range of general exhaust applications where low and medium ranges of air volume and pressure are specified. Applications include virtually all types of light manufacturing, commercial and institutional buildings such as shopping centers, hospitals, schools, hotels, office and apartment buildings, warehouses, airports, bus terminals, and many others.

Sizes 12 to 52

250 to 45,000 CFM

to 2" Static Pressure

General exhaust fan designed for spot ventilation of problem areas in single or multi-story structures. Such applications include warehouses, garages, plants, sports arenas and athletic clubs, hospitals and shopping centers.

Sizes 06 to 24

150 to 5,000 CFM

to 2" Static Pressure

Axial Roof and Wall Exhaust and Supply Fans

Wall Propeller Fans, Belt Driven and Direct Driven

A general ventilation fan designed for efficiency and economy.

Suggested for use in commercial and industrial applications including factories, warehouses, gymnasiums, underground parking garages or any area requiring ventilation where side wall mounted fans are desirable.

Our propeller fans are rugged and dependable. They are available in a large selection of CFM's and pressures.

The fans can be arranged for exhaust or supply use.

A wide choice of accessories are available to complete a well-balanced and specifically engineered air movement system.

General ventilation power roof ventilators designed for efficiency and economy.

Low profile PRVs are suggested for use in commercial and industrial applications including factories, warehouses, commercial buildings, machine rooms or any situation requiring the movement of air.

High profile PRVs are suggested for use in industrial

applications where it is necessary for the fan assembly to be located

above the roof

and where motor, belts and bearings must be isolated from the

airstream.

These upblast power roof ventilators are designed for long life, low maintenance and all-weather performance.

The proven upblast design is the most cost effective roof exhauster built today and offers the best value of all PRV types.

With many commercial and industrial buildings such as factories, warehouses, parking garages, shopping malls and department stores a means of venting hot gases and smoke in the event of a fire is required.

Our Type H PRVs are especially designed, built and proven by independent test to meet this essential need. They reliably extract large volumes of hot gases and smoke regardless of building configuration, location or weather conditions. They withstand high temperatures for long periods.

A reliable ventilation system that can operate during a fire is both vital and essential. It prevents smoke logging, allows people to escape quickly, minimizes damages to property and contents and enables firemen to attack the fire without hindrance.

These PRVs have the added advantage of providing normal day-to-day ventilation and in many cases can also be fitted with ductwork for use in multi-story buildings.

The unique Type H power roof ventilator concept provides a solution for emergency heat and smoke venting that is dependable under the most extreme circumstances.

6,500 to 120,000 CFM

to 3/4" Static Pressure

Sizes 24" to 60"

LOW PROFILE DIRECT DRIVE AXIAL ROOF VENTILATORS

2000 to 55000 CFM

to1" Static Pressure

Sizes 18" to 60"

HIGH PROFILE BELT DRIVE AXIAL ROOF VENTILATORS

2,000 to 100,000 CFM

to 1.5" Static Pressure

Sizes 24" to 60"

HIGH PROFILE DIRECT DRIVE AXIAL ROOF VENTILATORS

2500 to 65, 000 CFM

to 1.5" Static Pressure

Sizes 18" to 60"

General ventilation power roof ventilators designed to move large volumes of air quietly, efficiently and dependably.

They are suggested for use in commercial and industrial applications including factories, warehouses and large commercial buildings.

These rugged PRVs are available in a broad range of CMFs and a variety of configurations.

There are types offering belt and direct driven propellers, exhaust, supply or reversible are movement, and filtered air supply.

Most hooded PRVs can be supplied less fan component for use as a gravity ventilator or as an air intake.

Combinations of these various types can be used and still maintain a uniform and attractive rooftop appearance.

Use of the power combination of hooded power roof ventilators assures an effective ventilation system at exceptionally low cost.

Type RE recirculators are multi-purpose power roof ventilators.

They are suggested for use in commercial and industrial applications where there is sufficient ceiling height to create a temperature differential between the floor and ceiling.

These applications include factories, warehouses and large commercial buildings.

Type RE recirculators function as normal power roof ventilators in warmer weather and as an energy saving recirculation system in cold weather.

Each unit is equipped with a reversible fan that redistributes warm ceiling air throughout the plant and reduces the building's heating requirement. WIth the flip of a switch, it can function as a conventional roof ventilator.Never before has the need for adequate workspace ventilation been clearer to safety experts. Factories, warehouses, mines, offices and all other places where workers spend their time must be adequately ventilated and heated or cooled in order to minimize risks to air quality and maximize comfortable conditions, which contribute to productivity.

Canada Blower axial fans and centrifugal blowers, in high velocity and other configurations, are used to move air through ventilation systems and remove air through exhaust ports. The agricultural, photography, automotive, food processing, packaging, paper making, printing, welding and textile industries all use industrial blowers for workspace ventilation and a host of other applications, some of which are moisture reduction in bathrooms, spas and gyms and cutting down on smoke and odors in cooking and food processing.

Canada Blower centrifugal floor dryer blowers are widely used to dry carpet after cleaning. They are also used in building maintenance applications to dry spills or clean up after water damage.

Canada Blower industrial blower can be designed in one of two configurations. Axial blowers, which are more easily recognizable to most people, feature curved ventilator blades that spin around a blower axis. The spinning motion of axial fan blades closely resembles the motion of the spinning hands on a clock. The curvature of the blower blades creates an imbalance of air pressure on either side of the fan. The difference in air pressure causes airflow. When the blades spin continuously, the blower airflow is continuous.

The same principle of pressure imbalance applies to the other fan configuration as well. Radial (or centrifugal) fans also feature spinning ventilator blades, but radial fan blades spin within the confines of an enclosure (which is called an annular housing), and their spinning motion more resembles that of waterwheel paddles than of clock hands. As the blades (which are called impellers) within a centrifugal fan spin, they draw air from the side of the fan into the enclosure.

The blower impellers create a quick airflow. That quickness is augmented by the effect of centrifugal motion because of the shape of the annular housing. The result is that a centrifugal fan can produce a higher-pressure flow of air than can an axial fan operating at the same RPM. This feature makes centrifugal fans more attractive than axial fans in many industrial applications.

2,500 to 40,000 CFM

to 3/4" Static Pressure

BELT DRIVE EXHAUST / SUPPLY AXIAL ROOF VENTILATORS

Exhaust - Belt Drive: 4,000 to 95,000 CFM

to 3/4" Static Pressure

Supply - Belt Drive: 3,000 to 110,000 CFM

to 3/4" Static Pressure

BELT DRIVE TWO WAY-THREE WAY-FOUR WAY AXIAL POWER ROOF VENTILATORS

Exhaust/Recirc - Belt Drive: 4,500 to 50,000 CFM

to 1/2" Static Pressure

Exhaust/Supply/Recirc - Belt Drive: 2,500 to 40,000 CFM

to 1/2" Static Pressure

DIRECT DRIVE TWO WAY-THREE WAY-FOUR WAY AXIAL POWER ROOF VENTILATORS

Exhaust/Recirc - Direct Drive: 4,500 to 50,000 CFM

to 1/2" Static Pressure

Exhaust/Supply/Recirc - Direct Drive: 2,500 to 40,000 CFM

to 1/2" Static Pressure

With many commercial and industrial buildings, a means of venting hot gases and smoke in the event of a fire is required. Type H PRVs are especially designed, built and proven by independent tests to meet this essential need. They reliably extract large volumes of hot gases and smoke regardless of building configuration, location or weather conditions. The withstand high temperatures for long periods. These PRVs have the added advantage of providing normal day-to-day ventilation and and in many cases can be fitted with ductwork for use in multi-story buildings.

Belt Drive: 2,300 to 100,000 CFM

to 5/8" Static Pressure

When exhaust fans are used to provide ventilation, both for industrial and process exhaust and personnel comfort, a negative air pressure is created within the building. This negative pressure causes problems. Process exhaust systems are less efficient and may not work properly. Down flow can occur through gravity vents and result in the back venting of products of combustion from flues and stacks of heaters and process equipment. Drafts are created that are a discomfort to employees. Our Power Tube Fan Make-Up Air System solves all of these problems economically, even on the coldest winter day.

PT - 3,500 to 10,500 CFM

For the particular problems related to corosive environments, our offers the FG Fiberglass Fan. The FGS is molded in a one piece fiberglass housing unit that insures safety and efficiency of operation. The FG utilizes cast aluminum blades, all aluminum motor mounts and shutters to promote resistance to corrosion. These direct drive fans are designed for applications where a minimum of maintenance and economical operation are required.

1,985 to 11,800 CFM

High volume, heavy duty mobile air circulator for cooling factories, warehouses, garages, loading docks, processing lines or any other hot, inaccessable areas where people must work. MC Mobile Air Circulator can be rolled to wherever it is needed on four heavy duty casters.

5,000 CFM - 50,000 CFM

AXIAL DUCT FANS

Suggested for commercial and industrial uses such as make-up air systems, booster fans, return air fans or to exhaust contaminated or high temperature air.

Type T fans are available in a large selection of CFMs and operate efficiently against static pressures up to 2 inches.

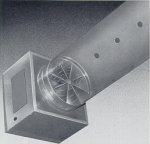

A true vane axial Type VA fan designed for use in a wide range of commercial or industrial applications.

High pressure efficiency permits the fan to be installed anywhere in the system; in any position. It can be used for either supply or exhaust by simply turning the entire fan unit to flow air in the desired direction.

Type VA fans are extremely compact and well suited to locations where space is limited. In many instances, these fans are mounted directly to the duct work.

As a result of very close tolerances and carefully matched vanes and rotor, the Type VA fan offers exceptional performance within its size range.

Belt Drive: 1,500 to 100,000 CFM

to 2" Static Pressure

DIRECT DRIVE AXIAL DUCT FANS

1,500 to 80,000 CFM

to 2" Static Pressure

VA DIRECT DRIVE VANEAXIAL FANS

VA - Direct Drive: 250 to 2,000 CFM

to 1 1/4" Static Pressure

IN-LINE CENTRIFUGAL FANS

The SB Square In-Line Centrifugal Fans are designed to provide

efficient air movement in ducted or non-ducted ventilation systems.

Designed for easy positioning and quick installation, the versatile

Square In-Line can be located inside equipment rooms, in ceiling spaces

or as parts for O.E.M. equipment.

SD

Direct Drive Square In-Line Fans

The SD Square In-Line Centrifugal Fans are designed to provide efficient air movement in ducted or non-ducted ventilation systems. Designed for easy positioning and quick installation, the versatile Square In-Line can be located inside equipment rooms, in ceiling spaces or as parts for O.E.M. equipment.

SD - Sizes 06 to 18

120 to 4,000 CFM

to 2" Static Pressure

SB - Sizes 12 to 36

250 to 25,000 CFM

to 3" Static Pressure

GRAVITY VENTILATORS

For Exhaust Relief Fresh Air Intake or Gravity Ventilation Systems. Modernistic low silhouette style to blend in with roof top lines and equipment. Designed with improved aerodynamically shape air flow passages.

Exhaust Relief Ventilators Models TE

Exhaust Relief Ventilators have a 1 to 1 ratio of hood perimeter opening to throat area.

Fresh Air Intake Ventilators Models TI

Fresh Air Intake Ventilators have a 2 to 1 ratio of hood perimeter opening to throat area.

Penthouses and Ventilators

The louvered look - a favorite selection for modern architectural eye appeal.

Penthouses - to dress up and beautify roof tops by enclosing unattractive mounted equipment viewed from higher floors and taller buildings.

Ventilators - For Exhaust Relief and Fresh Air Intake Ventilating Applications. Capacities up to 100,000 CFM.

Exhaust Relief Models LX

Exhaust Ventilators are designed for a maximum air velocity of 1200 fpm through the louvered openings and 1200 fpm through the throat.

Fresh Air Intake Models LN

Air Intake Ventilators are designed for a maximum inlet velocity of 600 fpm to reduce entrainment of rain or snow to a minimum. The maximum throat velocity is 1200 fpm.